we manufacture...

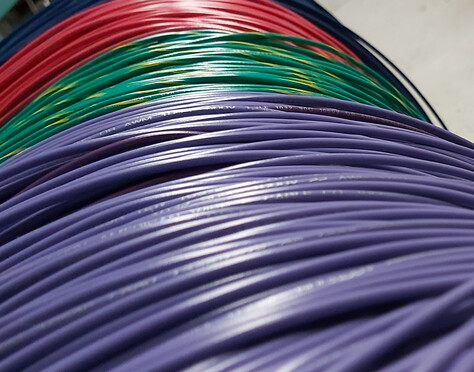

Electrical Wire Harnesses & Cables

For custom OEM products

Let US Prep Your Wires!

Design

We manage the process of creating custom wire harnesses for your product from conception to mass-production. Our factory & team works with your engineers to quote/audit your electrical wire specs, harness components and custom builds to specific requirements for the Fit, Form and Function of your custom designed Products. We build to certified drawings but can also help you design custom wirings inside a product if needed. Including site visits for scope and measurements, engineering, certified wiring best practices and consultation.

- Specifications

- Legal Requirements/ Certifications

- Physical Characteristics/Limitations

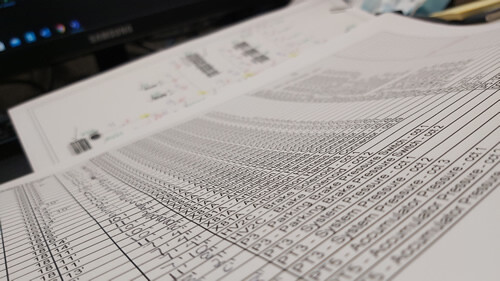

- Drawings & Spec Sheets

- Prototyping/ Sampling

- small run production

- ramped mass production

Innovate

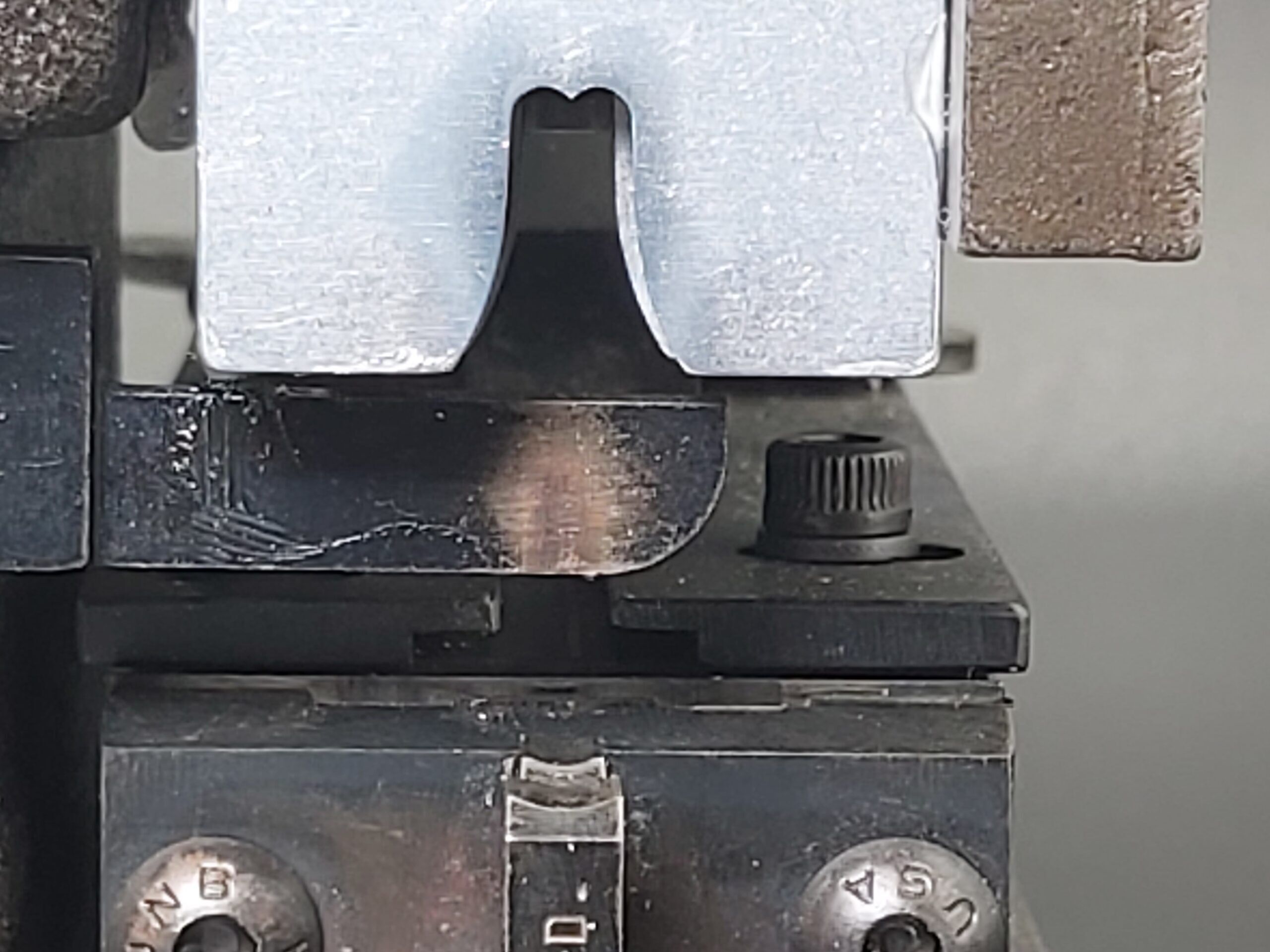

Once a harness design is finalized for a product and all aspects of the assembly process have been created, our assembly team goes to work manufacturing the product, while simultaneously auditing any and all processes involved with producing it to innovate assembly procedures for ramping at volume run rates. This process includes building/modifying/enhancing custom jigs & fixtures, implementing custom in-line processing tooling to assist assemblers as needed, and creating real-time harness tests/scanning to guarantee perfection at all costs. The assembly lines are built and adapt as products flow over time.

Deliver

Established Wire Harness, Cable and Lead product lines that we produce for OEMs can be ordered on a repeat basis as we store customer part data for future runs and help maintain part revisions throughout product lifespans. They are often ordered as blanket orders for higher volumes in order to procure stock at the best prices for you set on shipment release schedules to maintain part flow.

We aim to create manageable and repeatable lead times based on customer demand no matter the need using our long-standing supplier relationships so you will always be able to get your products in the amount you want, when you need them.

Experienced In Many Ways

Welcome To The Best Of IOT – System Design Methods

Latest

How To Find The Right Domestic Manufacturer To Process Electronic Wires

The Role Of Wire Harnesses In The Future Of Electronics

Electronics Supplier Relationship Management: How To Acquire New Suppliers

Electronic Components Shortages: Worldwide Effects Of The Pandemic

Capabilities

- Custom Cable Assemblies

- Certified Wire Respooling

- Custom Designed Assembly Jigs

- Certified Ferrule Application

- Lead-Free Wire tin Dipping

- Multi-Wire Cable Processing

- Single Ended High Volume Lead Wire Production

- Certified Terminal Crimp for all popular brands

- Custom Manufacturing Line Setups to Provide Production Support

- 24-12 AWG Certified Ferrule Application

- Mil-Spec D-Sub & HD D-Sub Soldering/installation

QUALITY IS A HABIT

Our Legacy Certified Processes coupled with new processing technologies perform Exceptionally well to Today's High Standards

Notable Projects

As a custom manufacturer, we quote on many different projects each year, some of which become large production programs that run the entire lifespan of a product. Below are products/programs we have been a part of:

Whirlpool Dishwashers

Produced a single ended multi-circuit power cable mass produced at volume that went into every unit during the program

Beam Vacuums

C-T Wire Prep Inc. Produced 3,000 dual ended lead wires a month for various internal power switch wiring applications. Parts consisted of a faston semi-insulated terminal applied to both ends for easy installation

Canadian Government Funded Solar Program

During the launch of the federally funded FIT program in 2009, Ontario became the global leader in Photovoltaic Energy Projects. C-T Wire Prep Produced all of the power feed wiring from panel to combiner box for over 10 large Ontario solar farms. Our engineering team designed a new method of manufacturing for the large cable runs using customized cutting machines to increase output to support high production rates.

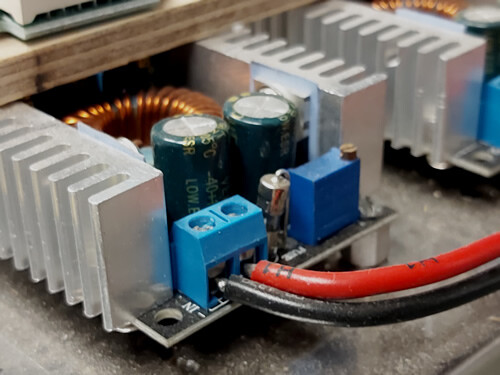

Transport Truck Sleeper Cab Climate Control Conversions

Created a custom engineered wiring harness complete with relays, fusing, weatherproof connections for a retrofit program aimed at lowering the carbon footprint of necessity powering of Transport Truck Sleeper Cabs. A small diesel generator unit with controls for A/C and Heating were added to transport trucks so the main engine did not need to run for those uses. Today, this design is part of the OEM build.

Gas Pump control wiring

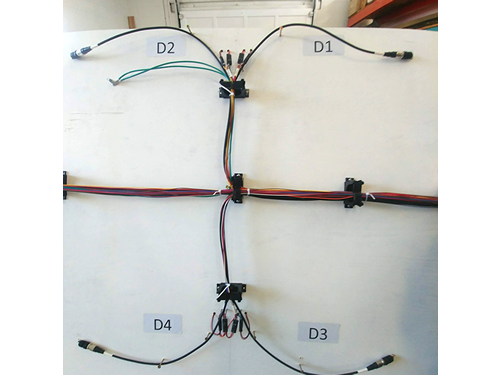

C-T Wire Prep Inc. produced volume production runs of a 7" multi-circuit board to board wire harness to connect power to different parts of the internal unit

Vending Machines

Custom spec'd power and sensor control harness to provide digital machine control and power supply across multiple internal devices

Commercial Food Industry Automation and Controls

Control panel boxes are often one-off designs in machinery, but once a product is standardized for an industry, it can be mass produced by a custom wire shop. We helped our client design a plug and play version of a panel box installed wiring harness pre-configured to allow mass production rates of the final product

WE GUARANTEE

Your Satisfaction

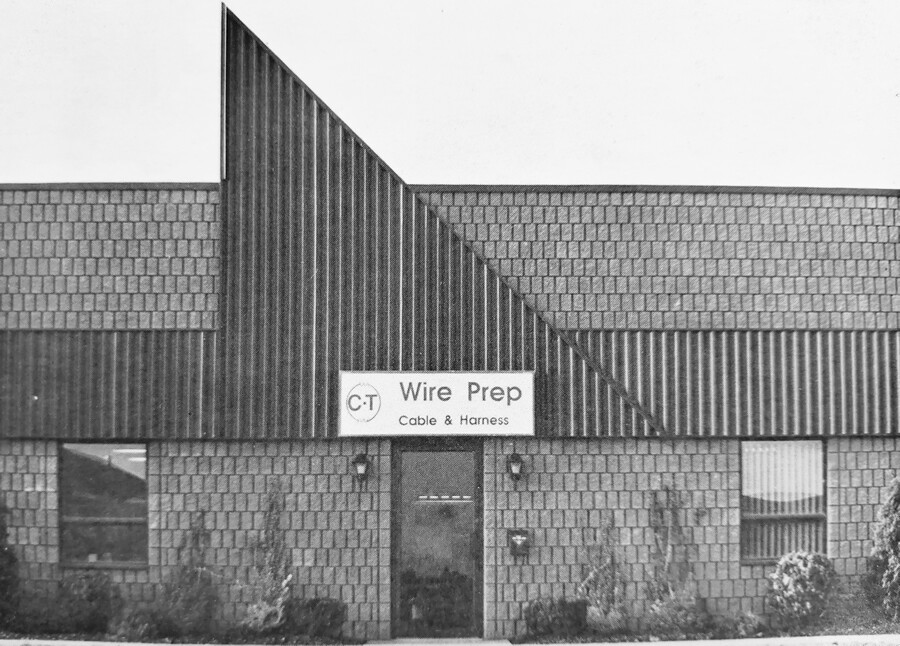

C-T Wire Prep Inc. Original Location In Cambridge, ON

Founded in June, 1991, C-T Wire Prep Incorporated broke ground as a brand new OEM Custom Wire Harness manufacturing company in Cambridge, Ontario, Canada. It was born as a family owned and operated business out of the wire shop within The Electrohome Company in Kitchener, ON who manufactured many of the popular electronics consumer brands throughout the 1900's.

Today, C-T Wire Prep Inc. is still family owned and operated and manufactures the same high quality CSA and UL certified custom cable and wire assemblies for various OEM's in St. George Ontario.

In 2008, C-T Wire Prep Inc. acquired a standalone manufacturing property in St. George, ON and moved manufacturing operations to better serve its customer base. More space to operate and property ownership has allowed the company to remain competitive in todays market and continue its legacy.

Companies have come to trust the high quality, reliability, certifications, and longevity that C-T wire Prep Inc. has established over the past 30 years in business and can be promised that same personalized service time and time again.

Our Customers - Love Our Service

Great working environment with high quality production materialsAbuzar

We've ordered some custom audio cables and components from this company for the studio. Great prompt, high quality products and second to none serviceSonic Alley Studios